Stop Leaks. Stop the Mess.

The Challenge Solved

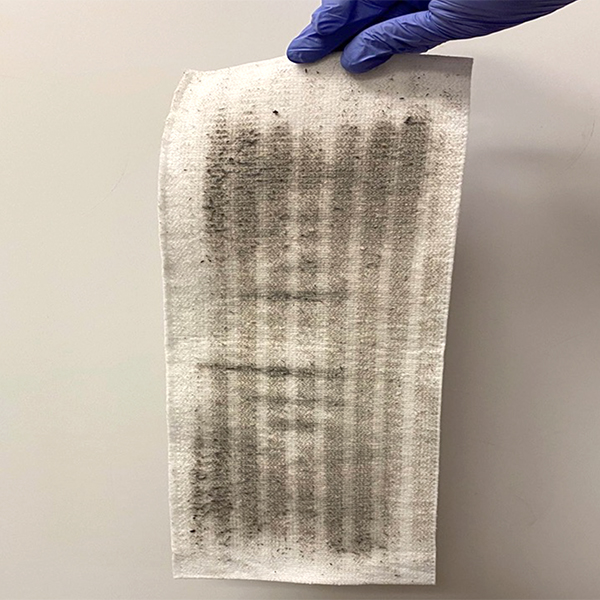

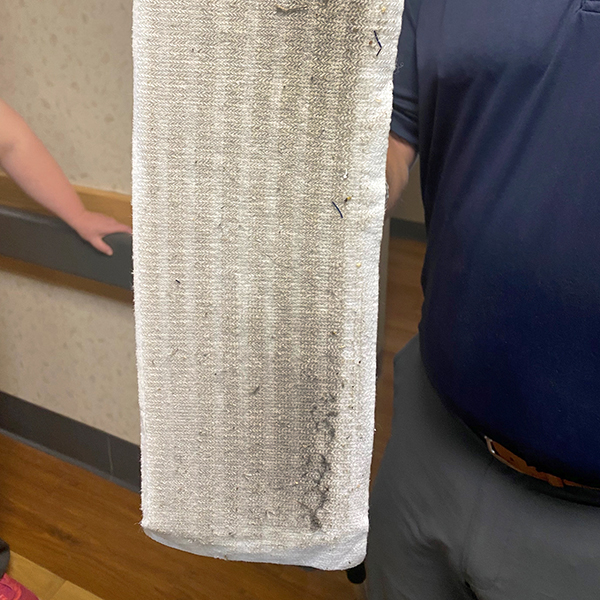

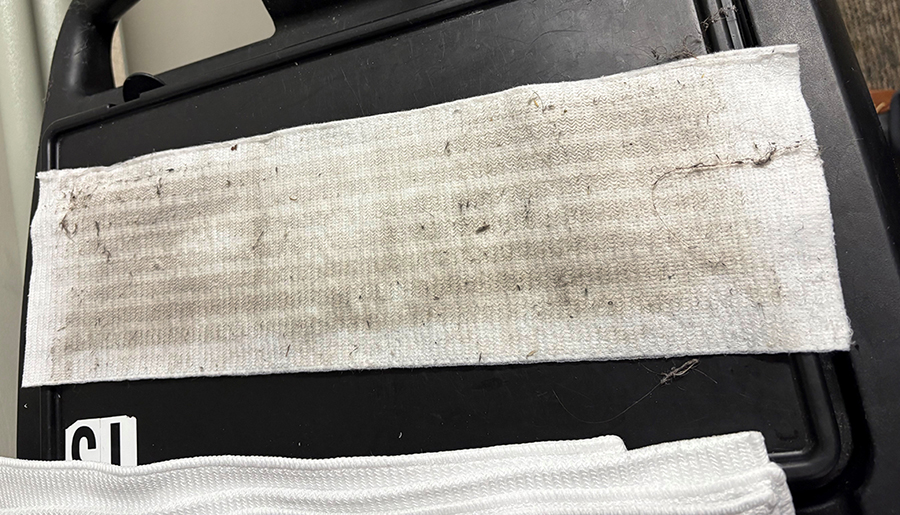

Leaking trash liners are a headache of the past. The Advantex® LeakLocker™ is the ultimate solution for messy trash leaks — an innovative, disposable absorbent pad that locks in up to 1 gallon (128 oz.) of liquid and keeps it there.

Advantex® LeakLocker™

Simply place a 14″ x 14″ LeakLocker™ pad in the bottom of any waste receptacle, collection container, or utility bulk box truck, and let it do the dirty work for days — until it reaches full capacity.

Perfect for: Stadiums | Theaters | Restaurants | Arenas | Schools

Anywhere leaking trash bags create extra work and mess!

Advantex® LeakLocker™ keeps your facilities cleaner, safer, and more efficient — so your team can focus on what matters. You will marvel at the results.

Geerpres® continues to lead the way in innovative EVS solutions, and LeakLocker™ is proof that small changes can solve big problems.