Mop Environmental Life-Cycle Analysis

The modular Enterprise® EVS cart is designed for the healthcare industry. The cart is customizable to suit various cleaning protocols.

Geerpres introduces the modular Enterprise® EVS cart, ideally designed for the healthcare industry and completely customizable to suit various cleaning protocols.

View New Products Feature

Hospital floors are constantly exposed to pathogens tracked in by shoes, wheelchairs, beds, carts, devices, and even patient socks, often making their way directly to beds. Adding to the risk, freshly laundered mops, assumed to be clean and frequently handled without gloves—can become a significant source of cross-contamination.

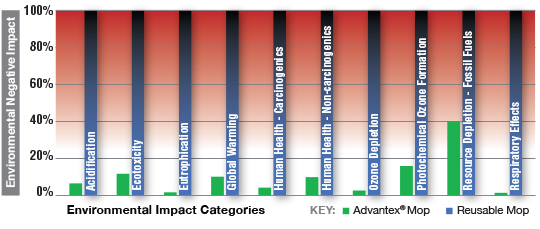

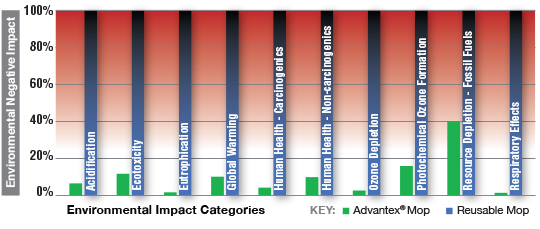

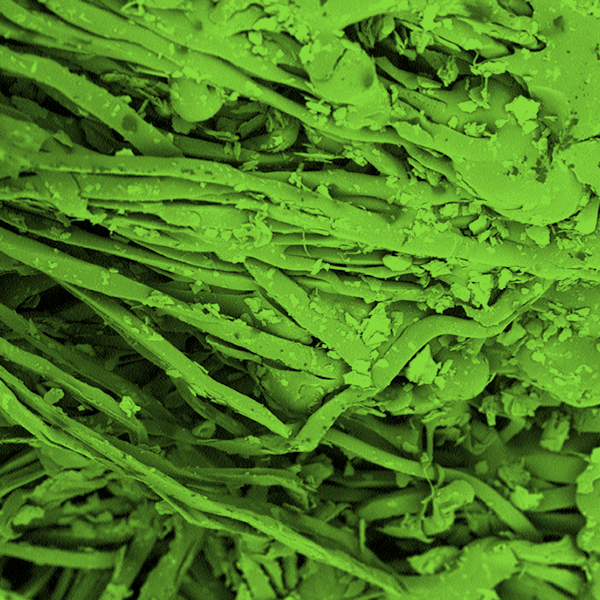

Studies show patient-room floors are frequently contaminated with HAI pathogens, including C. diff. Additional research found that 93% of laundered cloth and microfiber mops still carried viable microorganisms, highlighting the limitations of reusable cleaning tools.

Muskegon, MI, September 17, 2018: Geerpres® has a history of providing innovative cleaning products and supplies for healthcare, building service contractors, and EVS teams (Environmental Services). New to the Geerpres® lineup is the modular Enterprise® EVS cart, ideally designed for the healthcare industry and completely customizable to suit various cleaning protocols. The Enterprise® is at the heart of a comprehensive approach to advanced cleaning solutions. Pair it with Advantex® microfiber products and the leading EVS software management program for best-in-class outcomes including:

Muskegon, MI, September 17, 2018: Geerpres® has a history of providing innovative cleaning products and supplies for healthcare, building service contractors, and EVS teams (Environmental Services). New to the Geerpres® lineup is the modular Enterprise® EVS cart, ideally designed for the healthcare industry and completely customizable to suit various cleaning protocols. The Enterprise® is at the heart of a comprehensive approach to advanced cleaning solutions. Pair it with Advantex® microfiber products and the leading EVS software management program for best-in-class outcomes including:

Features of the Enterprise® EVS Cart

Company Contact:

(800) 253-0373

sales@geerpres.com