Advantex® Driving Innovation

Clean smarter.

Clean safer.

Clean with Advantex®.

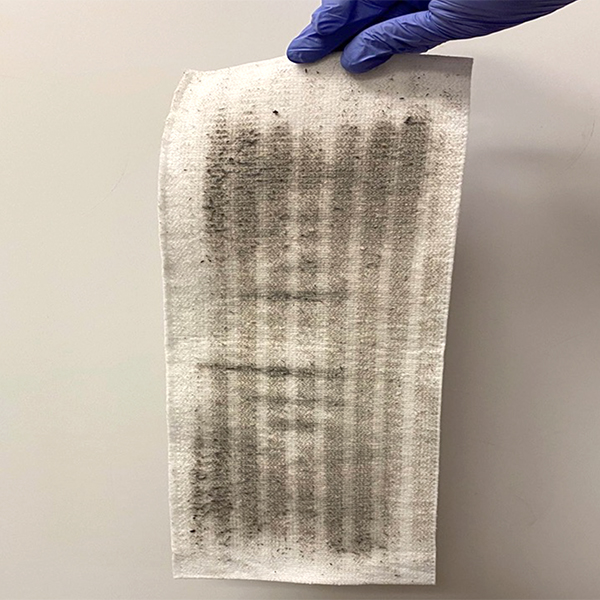

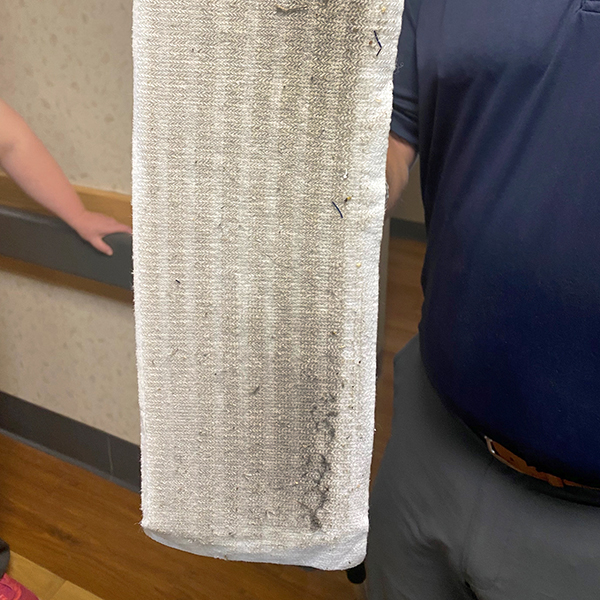

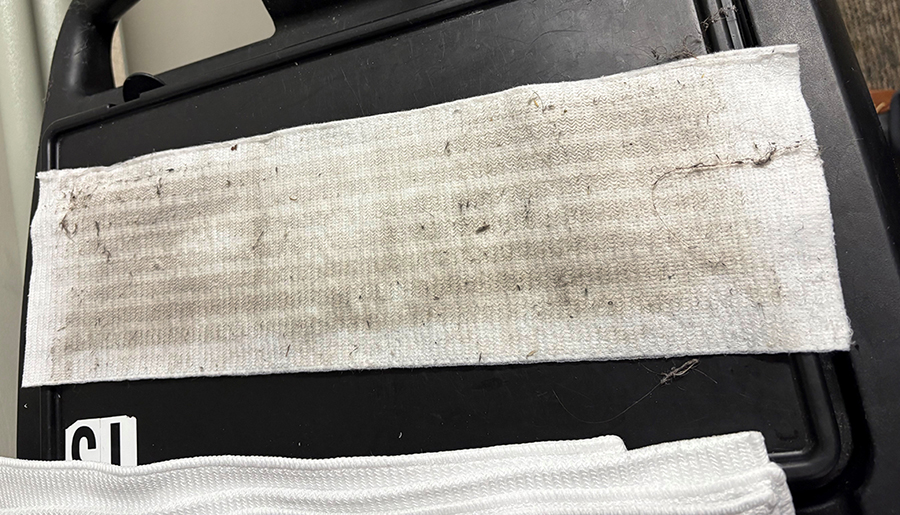

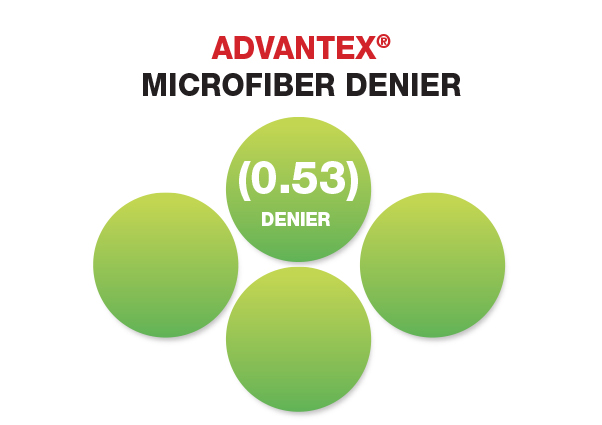

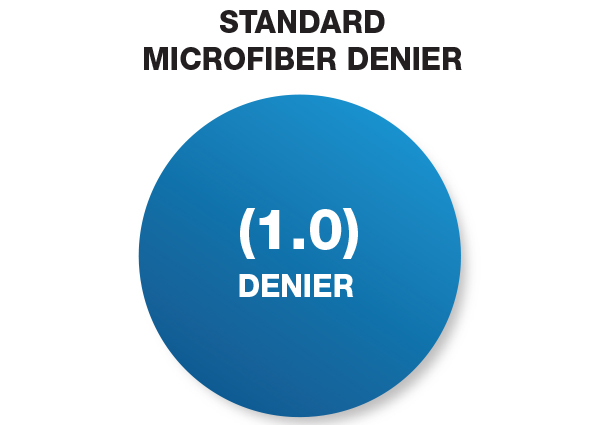

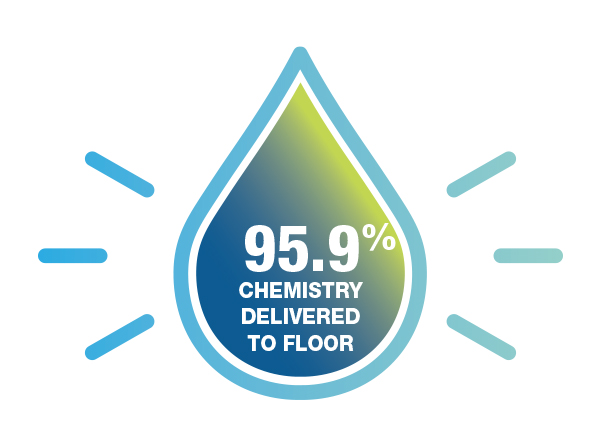

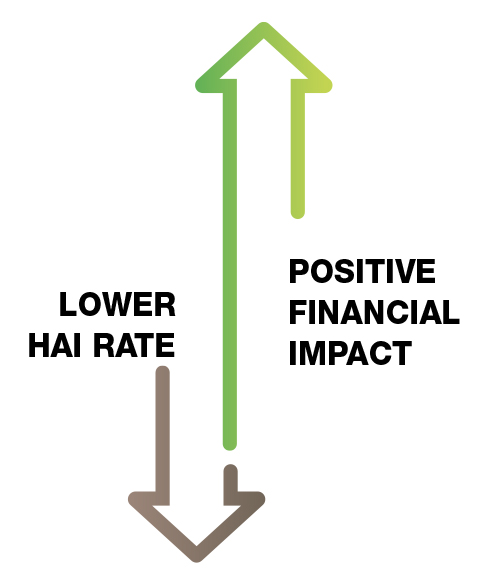

Geerpres® has a long-standing reputation for delivering innovative cleaning products and solutions. Our mission is centered on creating value and driving efficiency across the cleaning industry. In 2015, we introduced our Advantex® single-use microfiber flat mops—best-in-class tools designed to eliminate the risk of cross-contamination. Backed by research, these mops have set a new standard for hygiene and performance.

Today, our comprehensive product line includes a family of systematically designed solutions for healthcare, clinical, terminal, cleanroom, janitorial, educational, and food service environments. This includes patented self-dispensing microfiber applicators, disposable mops and wipes that virtually eliminate cross-contamination risks, and the industry’s only sustainable Loo-Mop.

Our complete line of Advantex® single-use microfiber products is systematically engineered for use across healthcare and clinical environments, terminal cleaning, cleanrooms, janitorial services, educational facilities, and food service applications.

-

ADVANTEX Microfiber Hand Duster

$98.84 – $111.20 -

Advantex® Single-Use Microfiber Mop

$102.38 – $144.48 -

Advantex® Spill Hero™

-

Advantex Sustainable Single-Use Loo-Mop (200 per case)

$226.57 -

Advantex Flat Mop Charging Bucket

$74.69 – $750.17 -

Advantex G8 Microfiber Applicator System

$155.34 -

ADVANTEX SINGLE-USE STRAP MOP (12 Per Case)

$79.43 -

ADVANTEX® 1/4 Fold Single-use Non-Woven Microfiber Wipes

$247.12 -

Advantex® Single-use Microfiber Wipes – Refill Rolls

$120.03 – $150.04 -

ADVANTEX Single-use Microfiber Wipe Dispenser Only

$19.56 -

Advantex Spill Mop

$255.94 -

Advantex Single-use High Duster Sleeve

$141.21